Custom fabrication collision revolutionizes automotive repair and restoration with precise, tailored solutions. Using CAD design, advanced tools, and expert craftsmanship, this method ensures perfect fits and finishes for unique vehicle architectures. Collision testing simulates real-world conditions to eliminate gaps and misalignments, enhancing both performance and aesthetics. These techniques are invaluable in creating custom replacement parts that fix scratches, improve durability, and set a new quality standard for vehicles.

In the realm of precision engineering, custom fabrication collision plays a pivotal role in achieving flawless results. This innovative process ensures that every component, tailored to unique dimensions and specifications, fits seamlessly into its intended system. Through advanced fabrication techniques, intricate details are crafted with meticulous care. Collision testing then verifies the perfect integration and finish, guaranteeing a high-quality, robust final product. By combining customization and precise collision, manufacturers can offer unparalleled solutions for diverse industries’ demanding requirements.

- Customization: Tailoring to Unique Dimensions and Specs

- Fabrication Techniques: Crafting Precision Components

- Collision Testing: Ensuring Seamless Integration and Finish

Customization: Tailoring to Unique Dimensions and Specs

In the realm of automotive craftsmanship, custom fabrication collision stands as a game-changer, offering unparalleled precision and tailored solutions. Unlike off-the-shelf parts, which often require modifications to fit unique vehicle architectures, custom fabrication collision ensures every dimension and specification aligns perfectly with your car’s specific make and model. This level of customization is particularly crucial for those seeking top-notch auto repair services or embarking on a car body restoration project, as it guarantees a seamless finish that enhances the vehicle’s overall aesthetics and performance.

The process involves meticulous measuring, advanced computer-aided design (CAD) software, and expert craftsmanship to create components precisely matching the client’s vision. Whether it’s frame straightening or crafting custom parts from scratch, this approach allows for a perfect fit, eliminating any gaps or misalignments that could compromise structural integrity or cosmetic appeal. Consequently, car enthusiasts and professionals alike benefit from enhanced driving dynamics, improved safety, and a restored vehicle that commands attention on the road.

Fabrication Techniques: Crafting Precision Components

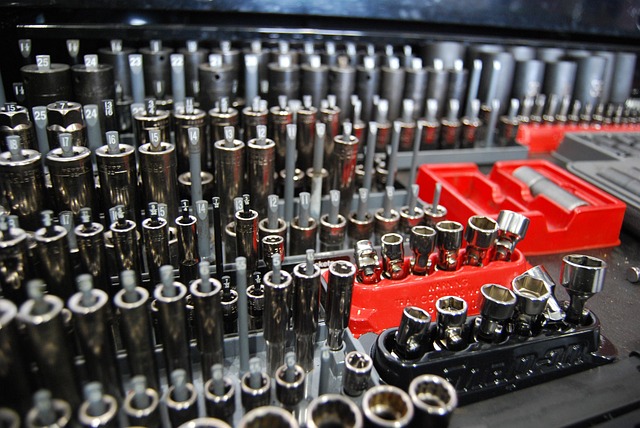

In the realm of custom fabrication collision, the art of crafting precision components is a cornerstone of achieving perfect fit and finish. Skilled artisans employ a myriad of techniques to transform raw materials into exact replicas of design specifications. From computer-aided design (CAD) software to advanced machining and welding equipment, every step in the process demands meticulous attention to detail. CAD models enable precise measurements and calculations, ensuring that each component is tailored to fit seamlessly with existing structures.

This level of customization is particularly vital in vehicle repair and collision scenarios where both functionality and aesthetics must be restored. Techniques like paintless dent repair offer a non-invasive approach, preserving the original factory finish while addressing structural dents. By combining traditional craftsmanship with modern technology, custom fabrication collision sets a new standard for quality, ensuring that vehicles not only drive smoothly but also maintain their striking appearance.

Collision Testing: Ensuring Seamless Integration and Finish

Collision testing is a critical step in custom fabrication, especially when it comes to achieving a perfect fit and finish. By simulating real-world conditions, fabricators can ensure that each component seamlessly integrates with the rest of the vehicle. This meticulous process involves subjecting parts to various forces and pressures to mimic accidents or damage, allowing for precise adjustments before final assembly. The goal is to eliminate any gaps or misalignments, ensuring a flawless finish that aligns with the manufacturer’s standards.

This method is particularly valuable in the auto repair shop, where repairing car scratches or other minor damages is a common task. Custom fabrication collision techniques enable technicians to create replacement parts tailored to the exact specifications of the vehicle, guaranteeing not only a visually appealing fix but also long-lasting durability. It’s not just about fixing a car scratch; it’s about maintaining and enhancing the overall aesthetic and value of the automobile through meticulous collision testing and custom fabrication.

Custom fabrication collision is a meticulous process that ensures every detail aligns perfectly. By combining customization, advanced fabrication techniques, and rigorous collision testing, manufacturers achieve exceptional fit and finish. This method is paramount in creating bespoke pieces that meet exacting standards, ensuring customer satisfaction through seamless integration and impeccable aesthetics.