Custom fabrication collision repair is a specialized automotive service addressing rare or missing parts through collaboration between skilled auto body experts and fabricators. This intricate process, requiring cutting-edge technology and meticulous craftsmanship, ensures precise fits and restores vehicles to pre-accident condition while meeting safety standards. Challenges include part scarcity, especially for older or specialized vehicles, leading to complex repairs and potential delays with associated costs. Auto collision centers overcome these hurdles through innovative strategies, including customized parts, supplier relationships, and digital tools for efficient part sourcing and inventory management.

In the realm of custom fabrication collision repair, where precision and efficiency are paramount, dealing with unavailable parts can pose significant challenges. This article explores the art of navigating part scarcity, delving into the strategies employed by experts to overcome these obstacles. We dissect the intricacies of custom fabrication in collision repair, shedding light on how skilled technicians ensure successful outcomes even when standard parts aren’t accessible. Understanding these methods is crucial for both professionals and enthusiasts seeking top-tier repairs.

- Understanding Custom Fabrication in Collision Repair

- Challenges of Unavailable Parts and Their Impact

- Effective Strategies for Handling Part Scarcity in Custom Fabrication Collision Repair

Understanding Custom Fabrication in Collision Repair

Custom fabrication collision repair is a specialized technique within the automotive industry, offering a unique solution to a common challenge: repairing vehicles with missing or difficult-to-find parts. When a collision occurs and standard replacement parts are unavailable, either due to obsolescence or rarity, auto body work experts step in with their expertise in custom fabrication. This intricate process involves crafting new components tailored to the exact specifications of the vehicle, ensuring a precise fit and restoring the car to its pre-accident condition.

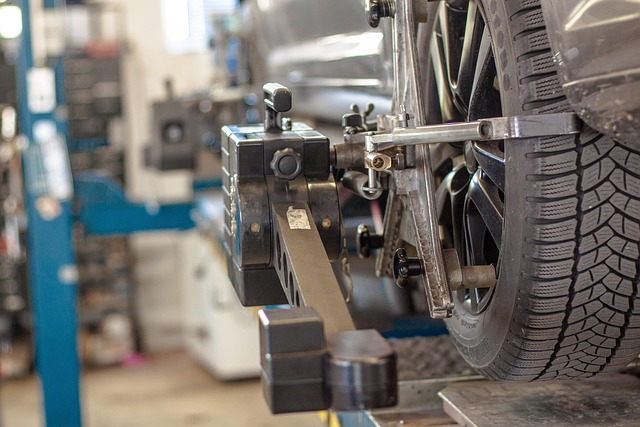

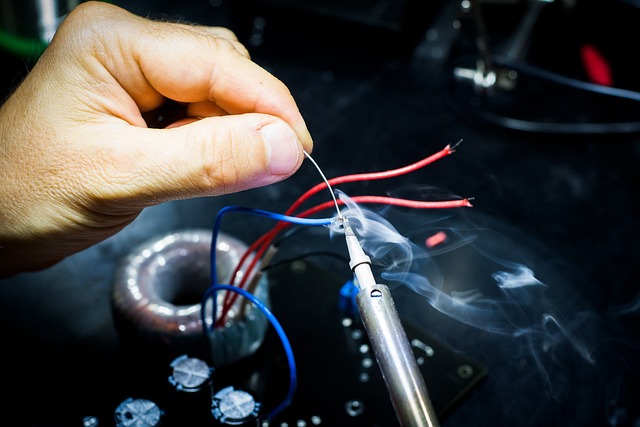

In many cases, collision repair shops collaborate closely with experienced fabricators who possess the skills and equipment to create these bespoke parts. By employing cutting-edge technology and meticulous craftsmanship, they can recreate even the most intricate designs, from bumper repairs to more complex body panel replacements. This approach not only preserves the vehicle’s original aesthetics but also ensures that it meets safety standards, making it a preferred method for collision repair professionals who want to deliver high-quality auto body work.

Challenges of Unavailable Parts and Their Impact

When a vehicle suffers damage in a collision, one of the primary challenges for custom fabrication collision repair specialists is the unavailability of replacement parts. In many cases, especially with older or specialized vehicles, finding exact matches for car body restoration can be difficult. This issue compounds the problem during complex repairs where every component must fit seamlessly to ensure optimal vehicle collision repair and a flawless finish.

The impact of unavailable parts extends beyond mere inconvenience. Delays in repairing a vehicle can lead to increased costs due to extended rental periods or storage fees. Moreover, using subpar or incompatible parts in auto painting or vehicle collision repair processes may compromise the structural integrity and aesthetic appeal of the vehicle, resulting in less-than-satisfactory outcomes for clients.

Effective Strategies for Handling Part Scarcity in Custom Fabrication Collision Repair

In the realm of custom fabrication collision repair, part scarcity can pose significant challenges. When a vital component is unavailable from standard suppliers, auto collision centers must employ innovative strategies to ensure timely and effective repairs. One proven approach is leveraging their expertise in customization; they can often fabricate or modify existing parts to fit the vehicle’s unique specifications, effectively bridging the gap left by scarce originals.

Additionally, establishing strong relationships with a diverse network of suppliers, including specialized manufacturers and aftermarket part dealers, becomes crucial. These connections enable access to hard-to-find components, even if they’re not readily available through traditional channels. Moreover, adopting digital tools for part sourcing and inventory management facilitates efficient tracking and communication, ensuring collision repair services remain uninterrupted despite part scarcity.

In the realm of custom fabrication collision repair, navigating part scarcity is an art. While challenges like unavailable parts can seem daunting, skilled technicians employ innovative strategies to overcome these obstacles. Through a combination of precision engineering, creative design, and access to advanced manufacturing technologies, they ensure that every vehicle receives the highest quality restoration, even when original parts are not readily available. This approach not only maintains the integrity of the vehicle but also perpetuates the vibrancy of the custom fabrication collision repair industry in today’s automotive landscape.